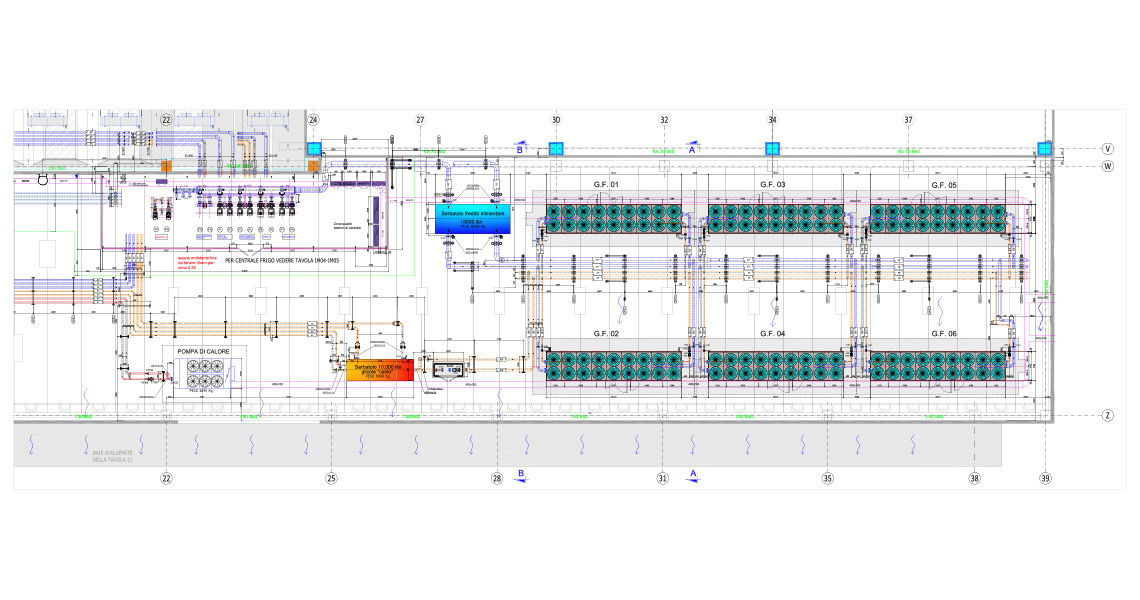

Logistics facilities and foodstuff storage

The refrigeration system used for the positive-temperature (TN) chambers is an INDIRECT Glycol system, while the negative-temperature (BT) unit adopts a CO2 Direct expansion system.

- Refrigerated covered surface of about 25,000 sq.m.

- TN chamber volume at an ambient temperature of +2°C, amounting to 260,000 m3

- BT chamber volume at an ambient temperature of -25°C, amounting to 7,700 m3

All the chambers and units are served by

LU-VE’s DRY COOLERSfor a total of 54 units and an overall power capacity of 4.0 MW.

The heart of the system is made up of

6 x 800 kW Chillers with a

R1234ZE refrigerant allowing to manage inertial storage with Glycol at

-8°C and to obtain heat recovery for a second storage at

+25°C, this second storage option at a positive temperature is used for thawing dry coolers through an exchange between the two cold and hot circuits.

This system allows for a

complete recovery of the potential energy requirement for thawing the exchangers, which would otherwise have been provided via other sources with associated costs.

Furthermore, the -8°C glycol serves the CO2 subcritical units of the

SCM FRIGO as condensation fluid, with machinery serving the -25°C BT chamber which is part of the system with the LU-VE Co2-expansion AIR EVAPORATOR.